AFFF Firefighting Foam Transition: Expert Insights from John Anderson, P.E.

As the regulatory landscape around PFAS continues to tighten, organizations nationwide, including airports and industrial facilities, are under increasing pressure to remove and replace AFFF firefighting foam. Once a cornerstone of fire protection systems, AFFF is now recognized as a major source of PFAS contamination and a growing liability.

With mounting environmental concerns, stricter regulations, and heightened public scrutiny, the need to transition to PFAS-free systems is urgent. But the path from compliance to complete decontamination is far from straightforward.

To help illuminate the complexity of this transition, we spoke with John Anderson, P.E., Senior Engineer at Revive Environmental and co-author of the peer-reviewed article Solutions for Managing AFFF-Impacted Infrastructure. Drawing on his deep field experience and research, John shares what facility managers need to know about AFFF firefighting foam, transition pitfalls, and how Revive delivers a complete, verifiable solution.

Understanding the Complexity of AFFF Transition

Q: You’ve worked with a wide range of AFFF transition projects. What makes AFFF removal and replacement a uniquely complex challenge from an engineering and regulatory standpoint?

John: These systems are life-safety systems. They’re installed to protect human life and property and are designed to remain active and in place, often without an option to isolate or bypass them. On top of that, PFAS-containing foams self-assemble on surfaces and create a waterproofing effect that makes PFAS very difficult to remove. Finding ways to effectively isolate, clean, and restore these systems is a critical piece of solving the AFFF challenge.

How Revive Supports Complexity:

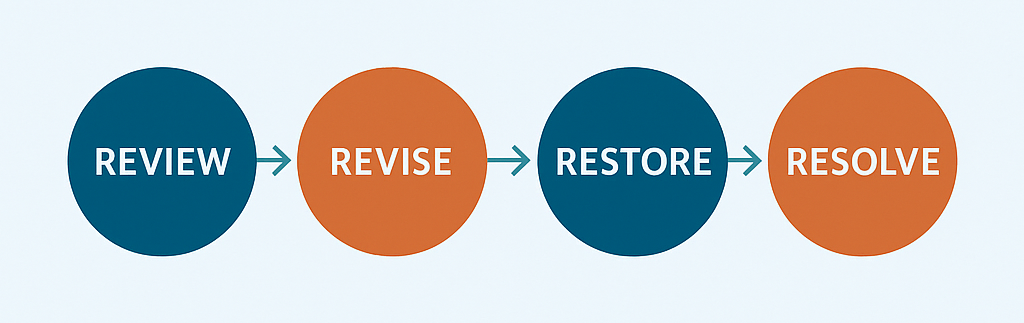

Revive’s approach begins with a comprehensive site assessment that evaluates foam specifications, infrastructure, and regulatory obligations. Our Review, Revise, Restore, and Resolve framework ensures that every aspect of the transition is coordinated and customized.

Real-World Challenges, Informed by Research

Q: In your recent journal article, several transition challenges are outlined. How do those align with what you’ve seen in the field?

John: The challenges are very consistent. In real-world projects, the need for cross-disciplinary coordination between fire protection, environmental, and engineering teams is one of the biggest hurdles. Each stakeholder has different concerns, and aligning them takes planning, technical depth, and operational insight.

Engineering-Led Strategy: The Revive Approach

Q: Revive’s framework includes stages like Review, Revise, Restore, and Resolve. Why is a staged, engineering-led approach so important?

John: Foam transition spans multiple disciplines—fire protection, firefighting operations, environmental engineering, and waste management. A phased approach helps manage those intersections and ensures each step supports both compliance and operational continuity.

Q: What are some typical issues you’ve seen during ARFF foam transitions? How does redesign help?

John: For fixed systems, you often need to modify equipment to handle the different application requirements of F3 foams versus AFFF. In vehicles, it’s usually a matter of adjusting the proportioning system. An engineering-led redesign ensures that transitions are both effective and efficient, minimizing downtime for those systems that are critical to remain operative.

How Revive Ensures Continuity:

Revive works with facility engineers and OEMs to deliver system redesigns that meet NFPA standards and fire protection needs. We handle planning, execution, and documentation to ensure compliance and continuity.

Going Beyond Water Flushing

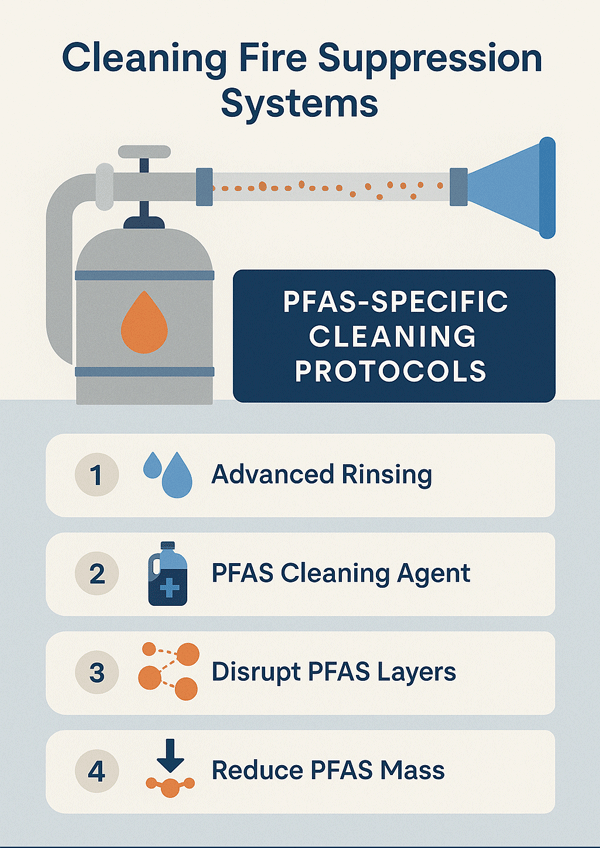

Q: The paper emphasizes that water-only flushing doesn’t entirely remove PFAS. What makes Revive’s approach more effective?

John: PFAS forms layers that water alone can’t effectively disrupt. Our approach uses advanced rinsing protocols and PFAS-specific cleaning agents to break those layers apart and significantly reduce PFAS mass remaining in the system. It’s about going beyond simply flushing and actually solving the contamination problem.

Q: How do these techniques help clients manage both cost and compliance?

John: Removing and replacing contaminated equipment is extremely expensive and disruptive. Our methods allow clients to keep existing infrastructure while still achieving important PFAS mass removal. That helps balance cost control with regulatory readiness.

How Revive Reduces Cost and Risk:

Our cleaning methods reduce PFAS rebound risk and preserve system functionality. By avoiding full equipment replacement, Revive helps clients stay compliant without halting operations.

From Cleanup to Verified Destruction

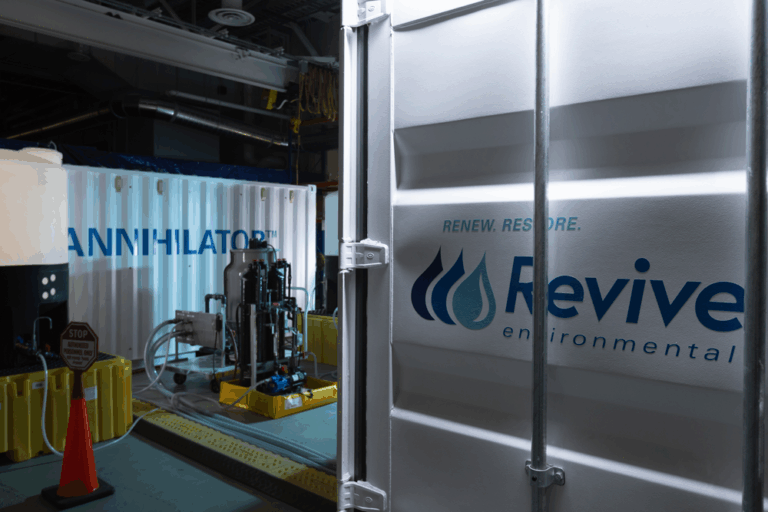

Q: You’ve evaluated many PFAS treatment options. What convinced you to join Revive and support the PFAS Annihilator® technology?

John: As a consultant, I researched every available option, from landfilling and injection to incineration and SCWO. The PFAS Annihilator® stood out for its ability to break the chain of liability. It doesn’t just move PFAS somewhere else—it destroys it. That kind of certainty is unmatched in the industry.

Q: How does verified destruction with a certificate of processing change the conversation with clients and regulators?

John: It’s transformative. With a certificate of processing and demonstrated mineralization, clients know they’ve eliminated PFAS completely—no intermediates, no long-term liability. It removes the risk of future litigation or cleanup demands. That peace of mind is powerful.

How Revive Closes the Loop:

Revive’s PFAS Annihilator® delivers over 99.99% destruction with third-party verification and full chain-of-custody documentation. We can deploy mobile units on-site or handle treatment at our off-site facilities.

Confidence Through Coordination

Q: Revive emphasizes minimal disruption and full chain-of-custody documentation. How important is that for your clients?

John: It’s critical. Especially for airports, military facilities, and industrial sites, there’s immense pressure to handle AFFF responsibly. Revive delivers not just technical solutions, but the assurance that liability has been managed and environmental protections are in place.

Q: What advice would you give to facility managers starting their AFFF transition journey?

John: Start early—earlier than you think. Ask questions. Get multiple stakeholders involved. And make sure your service provider can prove their track record. Foam transition isn’t just about replacing a product. It’s about protecting your facility, your community, and your future.

Learn More: Download Our AFFF Transition Service Overview

From system evaluation to complete PFAS destruction, Revive Environmental delivers comprehensive AFFF transition solutions designed for operational continuity and environmental assurance. Our PFAS Annihilator® technology, proprietary cleaning protocols, and phased engineering approach are trusted by state and federal agencies alike.

Download our AFFF Transition Overview PDF to see how Revive can guide your facility through a compliant, cost-effective, and liability-free transition.