Complete PFAS Destruction with Separation and Supercritical Water Oxidation

As environmental awareness and regulatory pressure intensify, the limitations of traditional PFAS remediation are becoming increasingly apparent. Many treatment methods transfer per- and polyfluoroalkyl substances (PFAS) into other media or break them into smaller but still harmful compounds, leaving waste generators vulnerable to future liability. For facilities that manage PFAS-laden water—from airports to landfills to industrial operations—a complete destruction solution is critical.

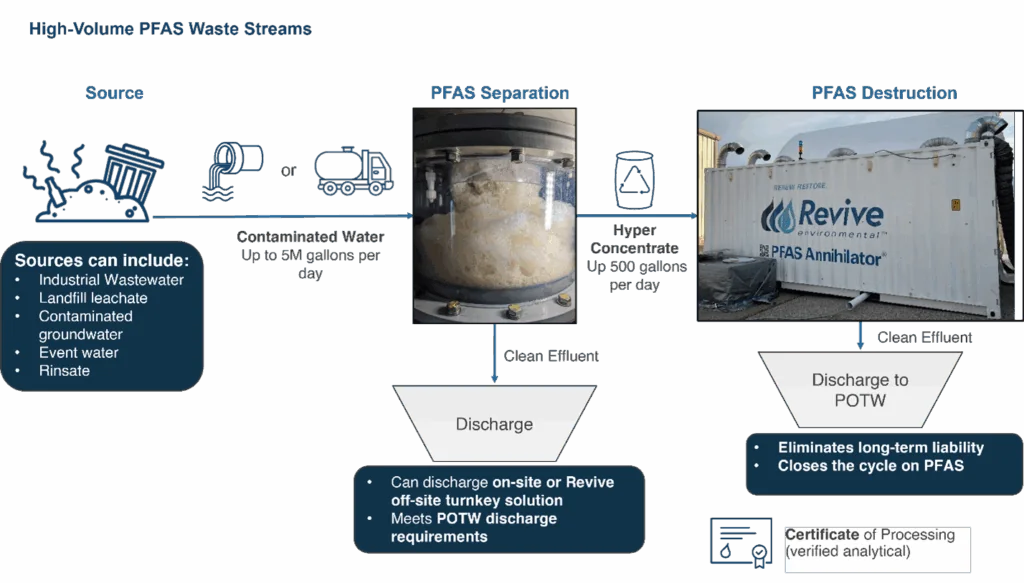

Revive Environmental offers a robust, proven approach that combines foam fractionation (FF) or reverse osmosis (RO) with supercritical water oxidation (SCWO). This integrated solution provides total PFAS elimination while reducing costs, ensuring compliance, and mitigating long-term environmental and financial risk. These combined technologies are particularly well suited to waste generators with large volumes of liquid discharge, offering scalable and effective treatment that integrates easily with existing operations.

PFAS: Ubiquitous, Persistent, and Regulated

PFAS contamination is widespread, affecting over half of U.S. drinking water sources. These synthetic compounds are used in firefighting foams, industrial processes, and consumer goods. As they resist degradation, PFAS accumulate in the environment, leading to health concerns and regulatory crackdowns.

Regulators are responding. The U.S. EPA’s recent National Primary Drinking Water Regulation established enforceable Maximum Contaminant Levels (MCLs) for six PFAS compounds, with limits as low as 4 parts per trillion (ppt) for PFOA and PFOS. Beyond federal actions, many states are implementing even stricter discharge standards and pushing for PFAS source control through permitting requirements. The regulatory landscape is also evolving to address disposal concerns, with pending rules that could restrict incineration and landfill options for PFAS-containing waste. As a result, industries are under pressure to identify permanent treatment options that ensure full compliance and minimize future liability.

To meet these stringent thresholds, more than 99.9999% removal may be necessary, a level unattainable with many legacy technologies.

Foam Fractionation and RO: Efficient PFAS Separation

Front-end technologies like foam fractionation and reverse osmosis play a vital role in concentrating PFAS from large water volumes. Foam fractionation uses air bubbles to extract PFAS, capitalizing on their surfactant-like properties. It is especially effective for long-chain compounds and can concentrate PFAS by factors up to 10,000x.

Reverse osmosis membranes, widely used in industrial and landfill settings, also separate PFAS into a high-strength reject stream. However, both methods generate PFAS-laden concentrate requiring safe destruction.

SCWO: Proven, Total PFAS Destruction

Revive’s PFAS Annihilator® leverages SCWO to permanently destroy PFAS compounds. In this process, water is brought above its critical point (374°C and 22 MPa), where it becomes a supercritical fluid. In this state, oxygen and organic compounds mix completely, enabling rapid and complete oxidation.

When PFAS concentrate is fed into the SCWO reactor with an oxidant, the extreme environment breaks carbon-fluorine bonds and converts PFAS into benign byproducts: carbon dioxide, water, and inorganic salts. Independent lab results consistently verify destruction rates of >99.99%, even for short-chain and fluorotelomer compounds.

Unlike thermal destruction or incineration, which can be incomplete and pose risk of airborne emissions, SCWO occurs in a closed system. There are no stack emissions, and there is no reliance on combustion. The process also handles organic co-contaminants effectively, with high energy efficiency when treating concentrated. Additionally, salts are managed through proprietary design features that prevent fouling and maximize uptime.

Real-World Deployments

While the PFAS Annihilator can be used as a mobile technology, Revive currently operates the majority of its units at two central PFAS destruction facilities: Columbus, Ohio, and Grand Rapids, Michigan.

Key benefits of the Revive model include:

Ideal Applications for PFAS Annihilator

SCWO combined with foam fractionation or RO is especially well suited to high-volume waste generators across sectors:

- Airports and Military Installations: Cleanup of legacy AFFF stockpiles and runoff from fire training areas.

- Landfills: Onsite or centralized treatment of PFAS-laden leachate to meet tight discharge limits.

- Industrial Facilities: Removal of PFAS from wastewater in metal plating, chemical manufacturing, or pulp and paper industries.

- Municipal Wastewater Systems: Managing concentrated PFAS reject from existing membrane systems.

These use cases benefit from SCWO’s ability to process complex waste streams, handle varying contaminant loads, and verify destruction to non-detectable levels.

The Future of PFAS Treatment

As PFAS regulations evolve, water treatment strategies must prioritize permanence and proof. Technologies that only shift the burden or create new residuals are no longer sufficient.

Foam fractionation or reverse osmosis paired with SCWO offers a scalable, commercially proven, and environmentally responsible path forward. By mineralizing PFAS to below the EPA’s stringent requirements, Revive Environmental empowers facility owners to confidently eliminate liabilities, protect downstream water quality, and ensure compliance for years to come.