What is Granular Activated Carbon Regeneration—and Why It Matters for PFAS Removal?

Granular activated carbon (GAC) has long been a cornerstone in water treatment—especially for removing persistent organic contaminants like PFAS (per- and polyfluoroalkyl substances). But what happens when your carbon becomes exhausted with those contaminants? Traditionally, the solution has been to transport the carbon offsite for thermal reactivation or dispose of it entirely (e.g., landfill, incineration). These approaches are expensive, time-consuming, and come with their own environmental trade-offs.

At Revive Environmental, we believe there’s a better way.

Understanding Granular Activated Carbon

GAC is an adsorptive filtration media made from carbon-rich materials processed to have a highly porous surface. These pores allow GAC to adsorb a wide range of contaminants from water, including synthetic organic compounds, disinfection byproducts, and PFAS.

Over time, as these pores fill with contaminants, the carbon becomes “spent” and loses its effectiveness. That’s when reactivation, regeneration, or replacement becomes necessary.

Why Regenerate Instead of Reactivate or Replace?

|

Criteria |

Replace |

Reactivate |

GAC RENEW |

|---|---|---|---|

|

On-site treatment |

❌ |

❌ |

✅ |

|

PFAS liability |

High |

Medium |

Very Low |

|

Downtime |

High |

High |

Low |

|

Environmental impact |

High (landfill) |

High (energy use, emissions) |

Low |

|

Traceable PFAS destruction |

❌ |

❌ |

✅ |

|

Reuse of GAC |

❌ |

✅ (make-up required) |

✅✅(multi-cycle) |

Replacing GAC outright introduces logistical burdens:

- Spent carbon exchange and transport of the wet media;

- Downtime while waiting for virgin carbon delivery;

- Long startup delays and wasted water for initial conditioning (e.g., metals, pH); &

- Increased PFAS liability with transport and landfill of the spent media.

Thermal reactivation—burning off contaminants at high temperatures—has historically been the only alternative for reusing GAC. But this method:

- Consumes significant energy in heating large volumes of media to >1200°F;

- Does not provide a batch-by-batch traceable record of PFAS destruction and may release PFAS into the atmosphere;

- Still requires shipping of spent and reactivated media; &

- The same startup delays as with using virgin GAC.

Enter GAC RENEW™, Revive Environmental’s solution for on-site regeneration of granular activated carbon that restores media performance while minimizing cost, disruption, liability, and environmental footprint.

How GAC RENEW Works

Our GAC RENEW technology regenerates GAC using a solvent-based, non-thermal extraction process:

- Regenerate: A proprietary regenerant solution is pumped into the spent GAC bed to extract the PFAS compounds.

- Recapture: The PFAS-laden solution is concentrated, and the solvent recovered through distillation.

- Destroy: The concentrated PFAS extract is processed through our PFAS Annihilator®, achieving >99.9999% destruction in a fully traceable and batch-by-batch analyzed and validated process.

- Return to Service: The regenerated GAC is rinsed and placed back online, ready to perform as effectively as, or better than, virgin carbon.

Assuming a standard lead-lag vessel configuration, throughout the renewal process the treatment system can remain online. That means no interruption to operations and no need for a replacement swing load.

Proven Results

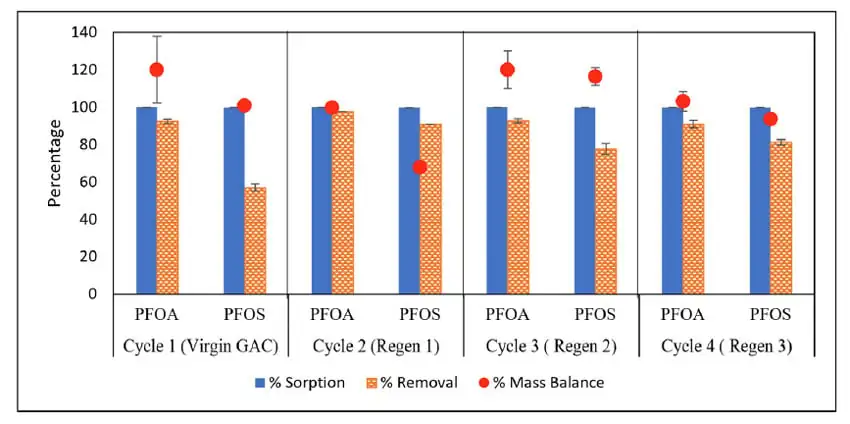

In one case study, solvent-regenerated GAC achieved consistent PFAS removal efficiency through four regeneration cycles, even outperforming virgin GAC during one of those cycles.

Combined with third-party validation and a Certificate of PFAS Processing via PFAS Annihilator, GAC RENEW offers confidence and compliance in one closed-loop solution.

A Better Approach to PFAS Risk Management

By regenerating GAC on-site, you:

Whether you operate a landfill leachate treatment system, industrial discharge stream, groundwater remediation system, or a municipal water facility, GAC RENEW provides a flexible, mobile, and verified solution that aligns with your operational goals and environmental responsibilities.

Granular Activated Carbon. Renewed and Reinvented.

Revive Environmental’s GAC RENEW is not an equipment upgrade—it’s a transformational shift in how we manage PFAS treatment. It restores the power of GAC without cutting corners or adding equipment—and closes the PFAS liability loop for good.